A Review Of DTF Transfer

When urgent, make sure your garment is completely flat and which the pressing floor is even, without collars or zippers in the way in which. It is important to take care of regular force amongst your warmth push as well as the transfer, which should DTF Transfer not be impeded by things of one's garment.

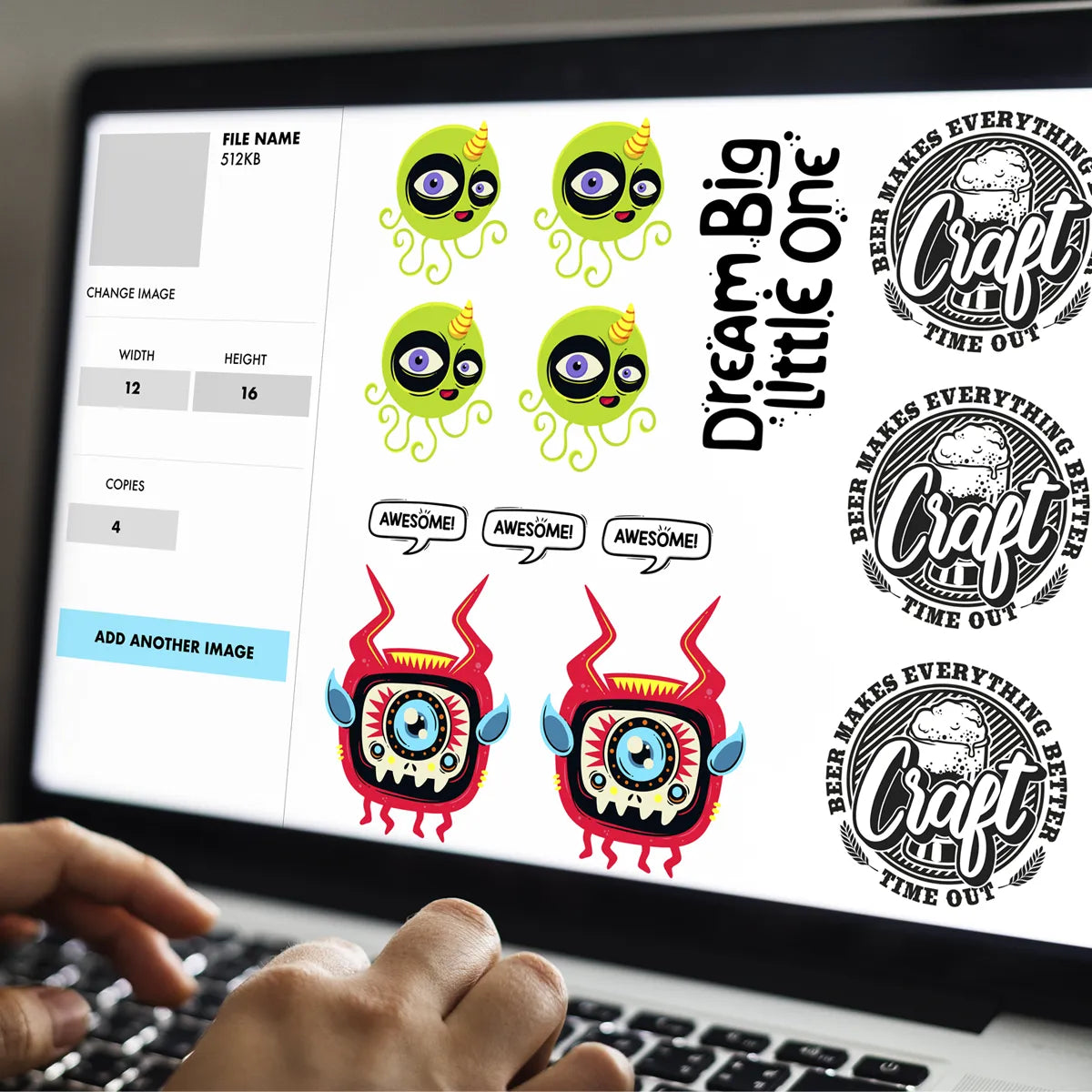

Vector artwork does not have this situation and will be equipped at any sizing due to the fact it can be scaled to any size without having negative results. For printing, we dimensions all artwork to become as big as is possible to the transfer sheet even though remaining proportional (as in, not stretched) Unless of course you request it at a certain size.

An higher Back print placement is commonly basically termed "Back," even so the significant difference is the placement goes up throughout the shoulder blades as opposed to vertically centered.

simple software: Simply location the DTF transfer on to your fabric, press it that has a heat press device at the proposed temperature, peel off the backing, therefore you’re carried out! the method is quick and user-pleasant.

First of all, you'll want to decide on the floor on which you will be printing and make an acceptable layout for that area. You can either draw your individual style digitally or use a pre-built structure.

This means you'll be able to keep your inventory lean and prevent the risk of overstocking or understocking. DTF warmth transfers also help you give you a broader range of merchandise without needing to spend money on a big stock upfront.

Price-successful: minimizes output prices by reducing the necessity for pretreatment and high-priced gear.

PET films are Utilized in DTF printers. These movies, using a thickness of 0.75mm, are superb elements that effectively transfer your designs onto products immediately after implementing heat and stress.

You can utilize Completely ready-made layouts or build custom types inside a electronic environment making use of style and design software package. Transfer your design and style into the DTF printer to execute the printing.

Additionally, sleeve and upper again placements provide one of a kind alternatives for smaller, but impactful layouts. Proper placement not just enhances the general aesthetics and also makes sure that the look complements the wearer’s type and aligns Together with the meant concept with the customized apparel.

renovate your textile printing abilities today with our unmatched DTF printing equipment assortment and witness the extraordinary impression of point out-of-the-artwork direct to movie printer know-how on your small business.

3. implementing the Adhesive: A powder adhesive is placed on the damp ink after printing. This adhesive enables the design to bond with The material when warmth pressed.

specialists trying to get additional insights can refer to “DTF that means in printing your apparent guide” and use the "DTF transfer placement information" and "optimal DTF warmth push settings guideline" for very best effects.

up coming, you should feed your structure to the DTF printer. The DTF printer uses inkjet technologies to transfer the look on to a PET film.